8 Essential Brake Maintenance Tips

Every time you take your vehicle out on the road, you rely on your brakes to respond quickly, smoothly and safely. But how often do you think about the condition of your braking system? While it's easy to overlook until something goes wrong, your brakes deserve regular attention to stay effective and reliable. From odd noises to warning lights, your brakes give plenty of clues when they need maintenance. The good news is, by following a few straightforward steps and knowing when to seek professional help, you can extend the life of your brakes and drive with confidence.

In this blog, we’ll discuss the essentials of brake care—what to look for, how to keep up with servicing, and when to let a specialist handle the details.

1. Know the Warning Signs Before It’s Too Late

Brakes don’t fail without warning. They often give subtle or obvious cues that they need attention. Learning to spot these early can prevent more serious damage or dangerous situations.

Look out for the following symptoms:

- Squealing or high-pitched noises when applying brakes

- Grinding sounds, which may suggest worn-down pads

- A soft or spongy brake pedal feel

- Vibrations through the pedal or steering wheel

- The car pulling to one side while braking

If you notice any of these signs, it's best to book a brake inspection immediately. Addressing these issues early can prevent costly repairs and ensure your safety.

2. Keep an Eye on Brake Fluid Levels & Quality

Brake fluid is a hydraulic fluid that helps transfer force from your foot to the brake system. Without it, your brakes won’t respond properly. That’s why it’s important to check the brake fluid level and condition regularly.

Here’s how to manage brake fluid:

- Check the fluid reservoir monthly for low levels or dark colour

- Top up with the recommended brake fluid if necessary

- Avoid mixing different types of brake fluids

- Have a complete fluid flush every 2–3 years or as recommended in your vehicle’s manual

Brake fluid naturally absorbs moisture over time, which reduces braking efficiency and can corrode internal components. Keeping it fresh is a simple but crucial task in maintaining brake performance.

3. Regular Brake Pad Inspections Save You in the Long Run

Brake pads gradually wear down with every use. Left unchecked, worn pads can damage rotors and affect braking efficiency, leading to longer stopping distances.

Car brake maintenance tips to help you monitor and maintain your brake pads:

- Inspect pad thickness every 10,000 km or during routine services

- Replace pads when they’re under 3mm thick

- Listen for squealing or metallic sounds that indicate wear

- Choose quality brake pads that suit your driving style and conditions

Routine pad inspections enhance safety and protect more expensive components, helping you avoid unnecessary repairs.

4. Don’t Ignore That Dashboard Brake Light

Modern vehicles are equipped with dashboard warning lights that illuminate when something’s not right. The brake warning light is one you shouldn’t ignore—it could indicate anything from low brake fluid to ABS issues.

Here’s what to do if your brake light turns on:

- Pull over safely and check the brake fluid level

- Ensure the handbrake is fully released

- If the light stays on or flashes intermittently, seek professional diagnosis

- Avoid driving long distances until the cause is identified

Ignoring this light may lead to system failure and compromise safety. A qualified technician can quickly identify the issue and ensure your brakes work properly.

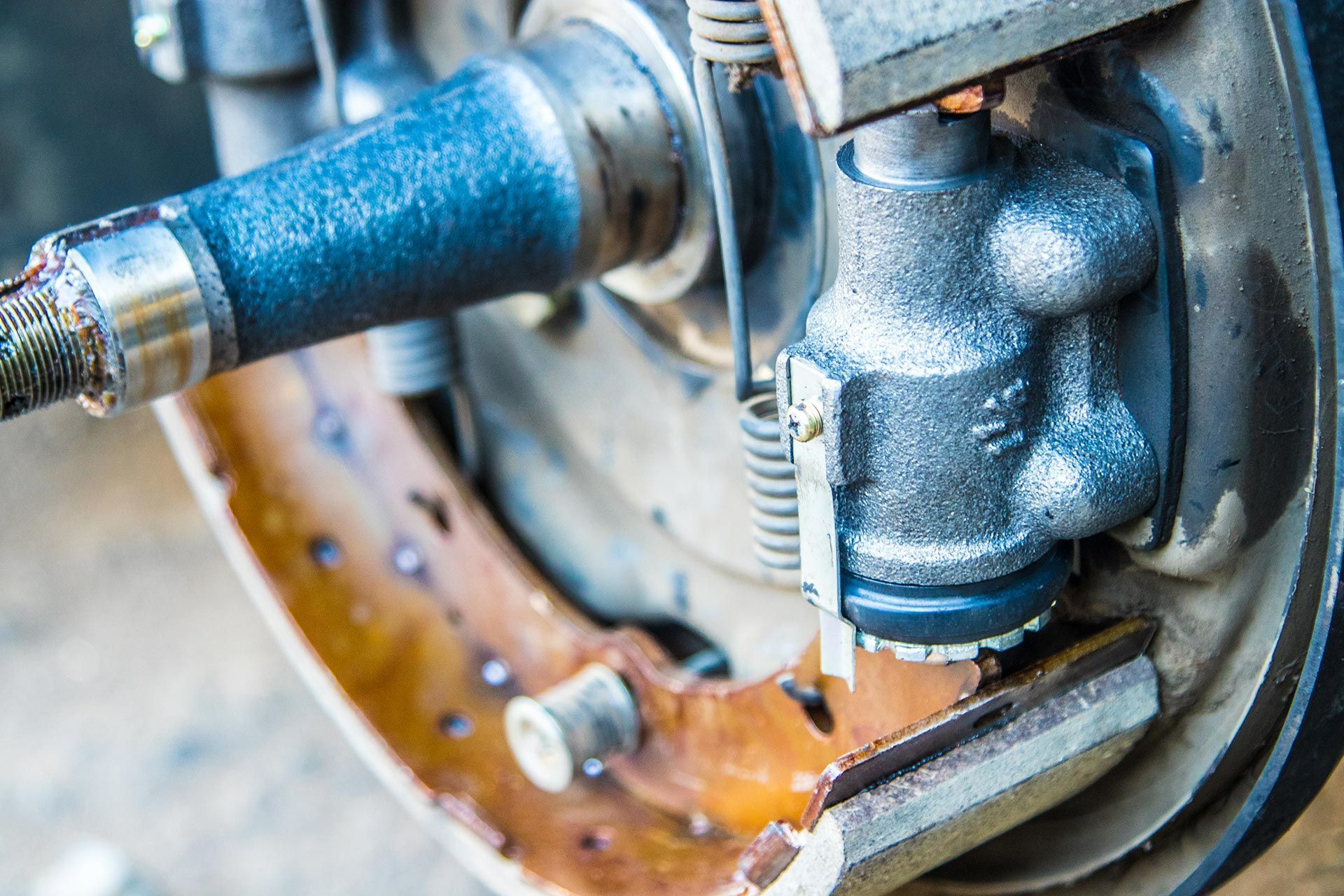

5. Understand the Role of Rotors in Effective Braking

Rotors, or brake discs, play a critical role by creating the friction surface your brake pads grip. Over time, they can warp or develop grooves, especially if brake pads are left too long before replacement.

Key facts about rotor health:

- Warped rotors cause vibrations when braking

- Deep grooves can reduce pad contact and stopping power

- Overheating leads to a blue or glazed surface on rotors

- Rust or corrosion is common in humid or coastal areas

Rotors can be machined (resurfaced) if the wear isn’t too severe. Otherwise, replacement is necessary to restore full braking performance.

6. Why Routine Brake Machining Makes a Difference

Machining is resurfacing rotors or drums to remove imperfections and ensure smooth braking. It’s a cost-effective way to maintain braking performance and extend the life of your braking components.

Advantages of brake machining:

Smooths out uneven wear and scoring

Reduces vibrations and noise during braking

Improves pad-to-rotor contact for better efficiency

Helps diagnose other potential issues like runout or warping

Brake machining should only be done if the rotor or drum is within the manufacturer’s minimum thickness. A specialist can assess whether machining or replacement is the better option.

7. Seasonal Checks Can Catch Issues Before They Escalate

Different weather conditions can affect how your brakes perform. Regular seasonal checks help spot wear or damage that may go unnoticed during daily driving.

What to look out for during seasonal inspections:

- After wet or muddy conditions, check for surface rust or debris

- Dusty environments can clog brake components or reduce pad life

- Heat and steep descents increase brake fade risk

- Cold weather may harden brake lines or affect fluid efficiency

Inspecting your brakes at the start of each season is a smart way to avoid potential issues and prepare your vehicle for changing conditions.

8. Trust a Specialist for Brake System Safety

While some aspects of brake maintenance can be DIY, many situations require professional expertise. Brake systems involve hydraulic pressure, precision parts and specific torque settings—all best handled by those with the right tools and knowledge.

Reasons to visit a brake specialist:

- Accurate diagnostics for complex issues

- On-site machining and testing equipment

- Access to quality components for repairs

- Experience across all vehicle types, including trailers, performance cars and vintage models

Professionals also handle custom work, such as brake hose fabrication, clutch hydraulics, and performance upgrades, ensuring your braking system is safe and suited to your vehicle’s use.

Looking After Your Brakes in Tamworth Starts Here

At Kings Brake Service Specialists, we provide top-tier brake services to keep you safe on the road. From comprehensive brake inspections and machining to custom hose manufacturing and hydraulic clutch repairs, our brake specialists in Tamworth offer professional services for all vehicles, including performance, vintage, commercial, and trailers.

Don’t wait for brake issues to affect your safety. Call us to book a service or get in touch with us via our

contact page. Let’s keep your

brakes working exactly as they should.