Why Timely Brake Repairs Are Crucial for Safety

Imagine cruising down a highway when the traffic ahead suddenly slows. You press the brake pedal—only to feel a delayed, weak response. It’s a frightening moment that no driver wants to experience. Brakes are the single most critical safety feature of your vehicle, yet many Australians put off brake repairs until it's too late. Whether it's a subtle squeak or a dashboard warning light, these early signs are your car’s way of asking for attention. Acting promptly not only ensures your safety but also helps prevent escalating damage and unnecessary costs.

Let’s explore how timely brake repairs keep your car safe, efficient, and compliant on the road.

The Danger of Ignoring Early Warning Signs

It’s easy to overlook faint squeals or a slightly spongy pedal. But these are often the first indicators that your braking system is compromised. Modern vehicles are designed to provide subtle but clear signs before failure occurs—if you’re paying attention.

Delaying a visit to your local brake specialist might cause:

- Brake pads wearing down to the metal, damaging rotors or drums

- Compromised brake fluid affecting hydraulic pressure and pedal response

- Uneven brake application, which can pull the vehicle to one side

- Reduced overall stopping power, especially in wet or downhill conditions

- Increased risk of complete brake failure during emergency stops

Early intervention allows technicians to address wear-and-tear before it escalates, restoring full braking performance and keeping you and your passengers safe.

How Brake Repairs Prevent Accidents

Every metre matters when it comes to stopping distance. Timely brake maintenance can mean the difference between a close call and a serious accident. In urban driving, where unexpected stops are frequent, well-maintained brakes are vital.

Here’s how prompt brake repairs enhance safety:

- Restoring full stopping efficiency reduces braking distance

- Replacing worn pads ensures even contact with rotors

- Resolving hydraulic issues maintains pedal responsiveness

- Eliminating brake fade prevents overheating during long descents

A delay in addressing small faults can translate into life-threatening risks on the road.

Why Professional Inspections Matter More Than DIY Checks

While it’s tempting to rely on a quick visual glance at your brake pads, this often misses deeper issues. Qualified brake technicians use specialised equipment to perform a full-system assessment, looking beyond just the pad thickness.

Technicians check:

Brake Pad & Rotor Thickness

- Accurate measurements with micrometres

- Checks for heat spots, scoring or uneven wear

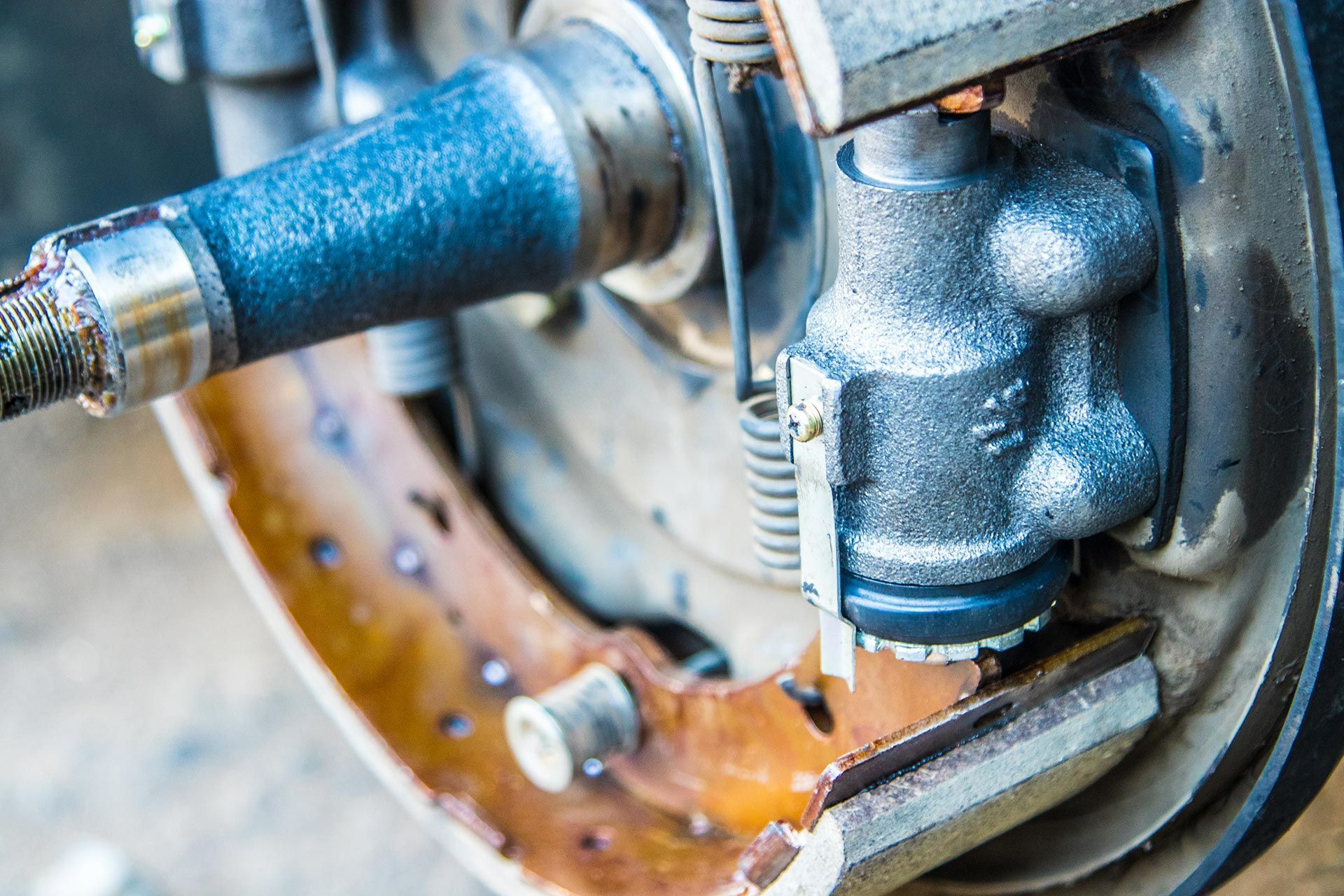

Hydraulic System Health

- Brake fluid moisture testing

- Leak inspections of cylinders and hoses

Vehicle Performance Tests

- Road test to detect vibrations or pulling during braking

- Brake bias testing for left/right balance

Professional inspections offer peace of mind and ensure nothing slips through the cracks.

The Role of Brake Machining in Restoring Performance

When your rotors or drums become uneven or scored, machining can often restore them without needing replacement. Brake machining involves resurfacing these components to eliminate imperfections and restore a smooth, even surface.

Benefits of brake machining include:

- Cost-effective alternative to rotor replacement

- Improved contact between pads and rotors

- Reduced brake noise and vibrations

- Prolonged lifespan of braking components

This process is especially valuable for performance vehicles, trailers and classic cars where sourcing parts can be more complex.

How Delays Can Increase Repair Costs

What begins as a simple brake pad replacement can quickly spiral into major repairs if ignored. Each part of the braking system relies on the next, so when one fails, others are often impacted.

Potential escalations include:

- Damaged rotors requiring replacement instead of machining

- Warped drums due to worn shoes or overheated components

- Contaminated brake fluid requiring a full flush and bleed

- Damaged callipers or wheel cylinders from uneven wear

Addressing issues early keeps your car roadworthy and helps you avoid the surprise of a much bigger repair bill later on.

Brake Maintenance for Different Types of Vehicles

Not all brakes are built the same. Different vehicles experience varying brake loads depending on their design, use, and weight. This means repair intervals and wear patterns also differ.

Passenger Cars

- Frequent stop-start driving causes faster pad wear

- Often benefit from routine machining to maintain smooth performance

4WDs & Trailers

- Heavier loads increase brake temperature and component wear

- May require upgraded pads or larger rotors for added safety

Classic & Performance Cars

- Brake machining can maintain factory specifications

- Requires careful inspection of ageing parts or reconditioned components

Customising your maintenance plan to your vehicle type ensures lasting performance and safety.

The Link Between Local Road Conditions and Brake Wear

Australian roads vary widely—from steep descents to pothole-ridden urban lanes. These conditions impact your brakes more than you may think.

Factors that increase wear:

- Steep gradients that require frequent braking

- Dust and gravel causing pad contamination

- Heavy traffic and short trips leading to constant stop-starts

- Urban environments that wear down brakes faster due to more frequent braking cycles

Being aware of your typical driving environment helps you predict when brake servicing is due. Regular inspections are vital in areas where terrain puts extra strain on your braking system.

When a Brake Repair Turns Into a Safety Upgrade

Sometimes, a brake repair is more than just a fix—it’s an opportunity to upgrade your system for better performance and durability. If your vehicle hauls heavy loads, tows a trailer, or sees spirited weekend drives, standard components might not be enough.

Upgrades often offered during brake servicing include:

- Slotted or vented rotors for heat dissipation

- High-performance ceramic pads for better fade resistance

- Reconditioned brake boosters and cylinders for consistent pedal feel

- Rebuilt clutch or master cylinders for restored hydraulic control

These enhancements not only improve safety but also reduce long-term maintenance needs.

Give Your Brakes the Attention They Deserve

At Kings Brake Service Specialists, we understand how crucial it is to act at the first sign of brake trouble. Our team specialises in brake repairs, machining and inspections tailored to your vehicle—whether it's a daily driver, a classic, or a performance machine. Don't wait until your brakes fail you. Get in touch via our contact page or give us a call for more information or to book a consultation or service. Let’s keep your car safe, responsive, and road-ready.